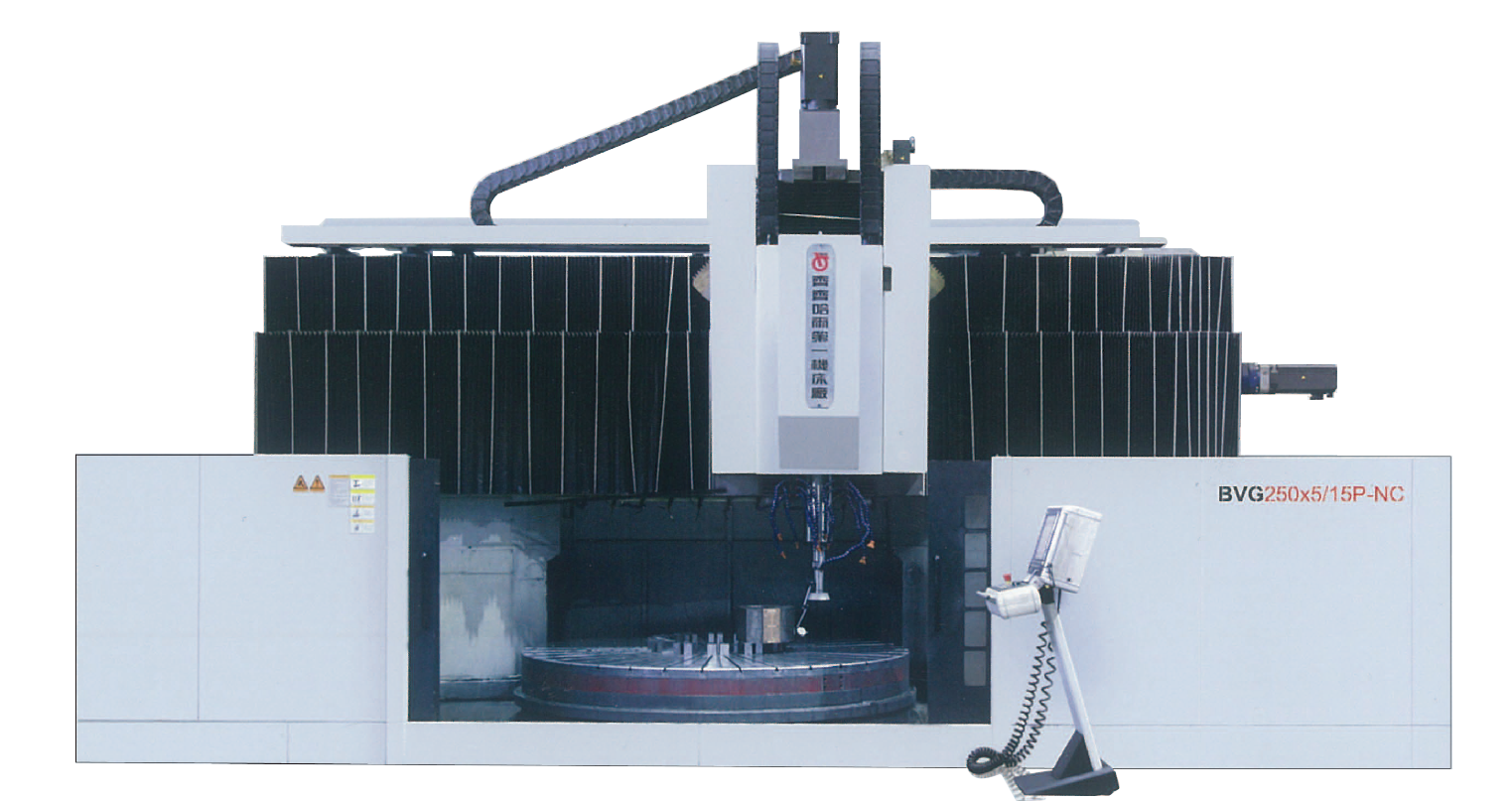

BVG Series

- This series of machine tools uses ceramic, resin bond and sintered diamond grinding wheels to grind parts of various carbon steel, alloy steel, cast iron and non-ferrous metal materials.

- The worktable feed is driven by a belt, and a Siemens 1FW6 torque motor is optional; the electro-permanent magnetic chuck is a Chinese excellent brand as standard, and the German brand SAV is also available as an option.

The worktable shaft and radial guide rail pair adopt high-precision closed hydrostatic guide rails, and the runout accuracy of the worktable end face and radial direction can reach 0.003mm. - Both the columns and beams adopt large-section box-shaped cast iron structures, and the horizontal movement of the beams uses closed static pressure guide rails.

- The tool grinding holder adopts a rolling grinding spindle with a spindle accuracy of 0.002mm; a double grinding tool holder is optional, and any combination of vertical and horizontal grinding tool holders is available.

The grinding stand is equipped with a B-axis, which is driven by a Siemens 1FT6 servo motor and uses circular grating feedback to achieve accurate indexing of the grinding head and vertical feed axis at any angle within +/-45 degrees. - The grinding wheel dressing device is a single-point grinding wheel dresser, optional arc grinding wheel dresser and diamond roller grinding wheel dresser.

Comprehensive cooling and protection, optional workpiece cooling refrigerator. - The CNC system adopts Siemens 828D.

- Surface roughness of grinding workpiece: plane and cylindrical surface Ra0.2μm, arc surface Ra0.4μm.

| Sepecification | Unit | BVG160x5/ 5P-NC |

BVG200x5/ 10P-NC |

BVG250x5/ 15P-NC |

BVG315x5/ 15P-NC |

BVG350x5/ 15P-NC |

BVG400x8/ 32P-NC |

BVG500x8/ 32P-NC |

| Max.machining diameter | mm | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 5000 |

| Max.height of workpiece | mm | 500 | 500 | 500 | 500 | 500 | 800 | 800 |

| Max.weight of workpiece | t | 5 | 10 | 15 | 15 | 15 | 32 | 32 |

| Max. height between table and cross beam | mm | 650 | 650 | 650 | 650 | 650 | 950 | 950 |

| Table diameter | mm | 1600 | 2000 | 2500 | 3150 | 3500 | 4000 | 5000 |

| Table speed step | stepless | stepless | stepless | stepless | stepless | stepless | stepless | |

| Table speed range | rpm | 1-30 | 1-30 | 1-30 | 1-15 | 1-15 | 1-15 | 1-10 |

| Horizontal travel of rail head | mm | 1750 | 1950 | 2100 | 2500 | 2700 | 3150 | 3650 |

| Vertical travel of rail head | mm | 600 | 600 | 600 | 600 | 600 | 900 | 900 |

| Rotation angle of rail head | ° | ±30 | ±30 | ±30 | ±45 | ±45 | ±45 | ±45 |

| Feed range of grinding head | mm/min | 0.01-1000 | 0.01-1000 | 0.01-1000 | 0.01-1000 | 0.01-1000 | 0.01-1000 | 0.01-1000 |

| Feed step of rail head | stepless | stepless | stepless | stepless | stepless | stepless | stepless | |

| Rapid travel of rail head | mm/min | 8000 | 8000 | 8000 | 8000 | 8000 | 8000 | 8000 |

| Speed range for rail head | rpm | 1500-3000 | 1500-3000 | 1500-3000 | 1500-3000 | 1500-3000 | 1500-3000 | 1500-3000 |

| Sand wheel diameter | mm | 260-400 | 260-400 | 260-400 | 260-400 | 260-400 | 260-400 | 260-400 |

| Motor power for table | kW | 18.5 | 18.5 | 18.5 | 18.5 | 18.5 | 37 | 37 |

| Motor power for spindle | kW | 22 | 22 | 22 | 22 | 22 | 22 | 22 |