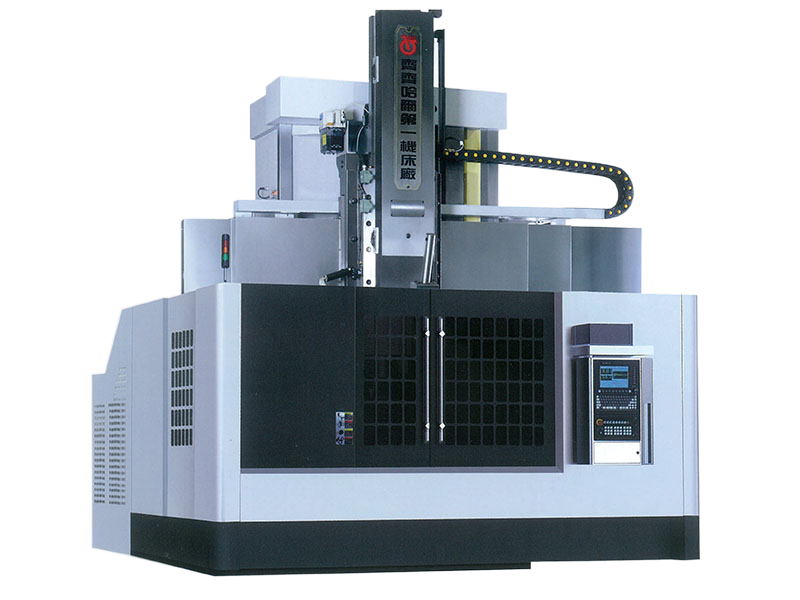

CK-E Series

- The machine is suitable for finely and roughly all kinds of ferrous, nonferrous metal workpiece for high speed steel's tools and hard alloy tools.

- The machine can be carried out turning inner & outer cylinder surface, cone surface, swivel curve surface, flat, grooving, thread etc. process machining.

- The main transmission is adopted D.C motor driven with two gears stepless adjusting speed. Encoder is fixed on the spindle with constant line speed cutting function.

- Guideway of table is adopted rolling guide way structure.

- Horizontal, vertical guideway of head are adopted wearable coating structure. It is realized horizontal, vertical two axes inter-motion and half close loop control.

- Half sealing guard of table is equipped, top water cooling system and chipping units are selected.

| Parameter | CK518E*8/2P-NC | CK5110Ex8/3P-NC | CK5112Ex10114V5P-NC | CK5116Ex(10)1416 8P-NC | CK5120E*(12)1620112P-NC |

| Max.tuming dia. (mm) | 800 | 1000 | 1250 | 1600 | 2000 |

| Table dia. (mm) | 720 | 900 | 1010 | 1400 | 1800 |

| Max.weight of workpiece (Metric Ton) | 2 | 3 | 5 | 8 | 12 |

| Max.machining height (mm) | 800 | 800 | 1000[1250] | (1000) 1400 [1600] | (1250) 1600 [2000] |

| Max.torgue of table (kNm) | 10 | 10 | 10 | 16 | 20 |

| Speed range of tble (rpm) | 3.15~315 | 3.15~315 | 25~250 | 2~200 | 1.6~160 |

| Step of tble speed | Steplesst(machinery II step) | Steplesst(machinery II step) | Steplesst(machinery II step) | Steplesst(machinery II step) | Steplesst(machinery II step) |

| Max.cutting force of raihead (kN) | 20 | 20 | 20 | 25 | 25 |

| Rapid speed of tool bead Xzaxis (mm/min) | 4000 | 4000 | 4000 | 4000 | 4000 |

| No.of tool head (No.) | 1 | 1 | 1 | 1 | 1 |

| Horizontal travelof toel head slidimg (mm) |

-20~650 | -20~650 | -20~830 | -20~1030 | -20~1230 |

| Vertical travel oftol bead ram (mm) | 650 | 650 | 650[800] | 800 | 800 |

| Tool head herizentalvertical guideway pair |

Sliding guideway | Sliding guideway | Sliding guideway | Sliding guideway | Sliding guideway |

| Max.vertical travel ef crossrail (mm) | 580 | 580 | 750 [1200] | (760)1210 [1410] | (1000) 1350 [1750] |

| Elevating speed of crossrail (mm/min) | 440 | 440 | 440 | 440 | 440 |

| Ram section of milhead (mm2) | 320x210 (T type) | 320x210 (T type) | 320x210 (T type) | 320x210 (T type) | 320x210 (T type) |

| Fracture surface sue of toel bur (mm2) | 30x30 | 30x30 | 30x30 | 30x30 | 30x30 |

| No.of turret | 4 positions vertical type(Yantai) | 4 positions vertical type(Yantai) | 4 positions vertical type(Yantai) | 4 positions vertical type(Yantai) | 4 positions vertical type(Yantai) |

| CNC System | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D | Siemens 828D |

| Cuting cooling system(cptional) | With | With | With | With | With |

| Automatic chip conveyorfoptional) | With | With | With | With | With |