| Parameters |

Unit |

SMVT630 |

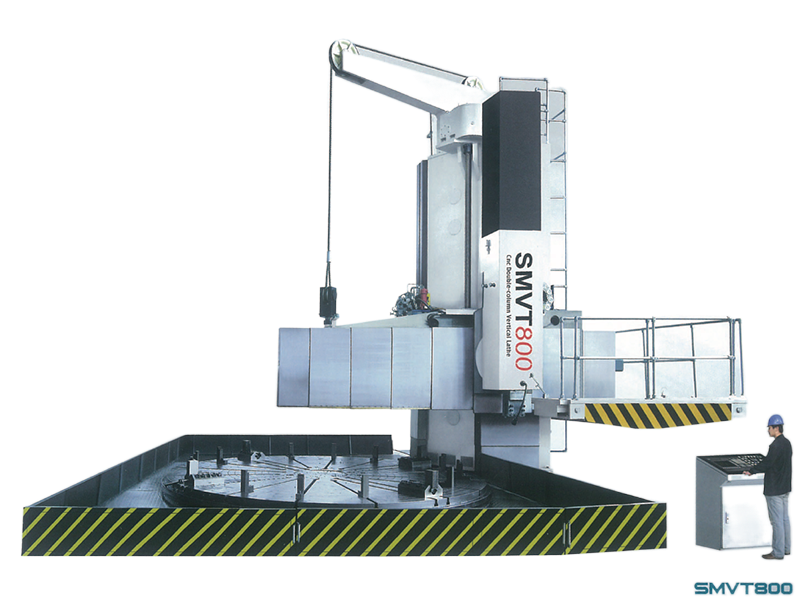

SMVT800 |

SMVT1000 |

SMVT1250 |

SMVT1600 |

SMVT1800 |

SMVT2200 |

| Max. turning diameter |

mm |

6300 |

8000 |

10000 |

12500 |

16000 |

18000 |

22000 |

| Max. height of work piece (including assistant jaw) |

mm |

3150 |

3150 |

4000/4600 |

4000/5000/5600 |

5000/6300/12500 |

5000/7500/12500 |

8000/12500 |

| Max. weight of work piece (ton)(including assistant jaw) |

t |

50 |

50 |

100 |

100/200/350 |

200/300/400/600 |

200/300/400/600 |

500/600/800 |

| Table diameter |

mm |

4000 |

4000 |

5700 |

5700/7100/8000 |

8000/7500 |

7500/10000 |

10000 |

| Max.turning diameter between railhead and center |

mm |

4000 |

4000 |

6300 |

6300/8000 |

8000/10000 |

8000/10000 |

10000 |

| Table speed |

|

Two-step/stepless |

Stepless |

Stepless |

Stepless |

Stepless |

Stepless |

Stepless |

| Speed range of table |

r/min |

0.5-50 |

0.5-50 |

0.32-32 |

0.16-16/0.20-20 |

0.20-20/0.16-16 |

0.20-20/0.16-16 |

0.16-16 |

| Feed revolution range of C axis |

|

0.0001-1 |

0.0001-1 |

0.0002-0.2 |

0.0002-0.2 |

0.0002-0.2 |

0.0002-0.2 |

0.0002-0.2 |

| Max. torque of table |

kNm |

160 |

160 |

320 |

630 |

500/630/800 |

500/630/800 |

800 |

| Rapid traverse of head |

mm/min |

4000 |

4000 |

4000 |

4000 |

4000 |

4000 |

4000 |

| Feed steps of railhead (stepless) |

|

Stepless |

Stepless |

Stepless |

Stepless |

Stepless |

Stepless |

Stepless |

| Feed range of railhead |

mm/min |

0.1-1000 |

0.1-1000 |

0.1-1000 |

0.1-1000 |

0.1-1000 |

0.1-1000 |

0.1-1000 |

| Max. cutting force of railhead |

kN |

50 |

50 |

80 |

80/100/125 |

100/125 |

100/125 |

125/160 |

| Horizontal travel of railhead |

mm |

2150 |

2150 |

3400 |

3400/4250 |

4250/4600 |

4300/5350 |

5650 |

| Vertical travel of ram for railhead |

mm |

1600 |

1600 |

2000 |

2500/3000 |

2500/3000/4000 |

2500/3500/4000 |

4000 |

| Ram section |

mm |

□240 |

□240 |

□280 |

□320/□360/□400 |

□360/□400/□550 |

□400/□460/□550 |

□460/□550 |

| Max. traveling angle of railread |

|

-15°~+30° |

-15°~+30° |

-15°~+30° |

|

|

|

|

| Max. travel of crossrail |

mm |

2600 |

2600 |

3000 |

3800/4250 |

4000/6000/10000 |

4000/5650/10000 |

6500/10000 |

| Lifting speed of crossrail |

mm/min |

228 |

228 |

280 |

250 |

280/200 |

280/200 |

100 |

| Max. travel of column |

mm |

1150 |

2250 |

2000 |

3100/2500 |

4000/4700 |

4100/5350 |

6000 |

| Column speeds |

mm/min |

200 |

200 |

200 |

200 |

200 |

200 |

100 |

| Power of main motor |

kw |

75 |

75 |

110 |

132 |

132/160 |

110/132/160 |

160 |

| Power of milling motor |

kw |

28/38 |

28/38 |

28/38 |

28/38/39/58 |

39/58 |

39/58 |

39/58 |

| Power of elevating motor for crossrail |

kw |

18.5 |

18.5 |

30 |

30/37 |

30/37/55/75 |

30/37/55/75 |

75 |

| Power of motor for column movement |

kw |

7.5 |

7.5 |

7.5 |

7.5/18.5 |

18.5/37 |

18.5/37 |

55 |

| CNC system |

|

SIEMENS840D |

SIEMENS840D |

SIEMENS840D |

SIEMENS840D |

SIEMENS840D |

SIEMENS840D |

SIEMENS840D |