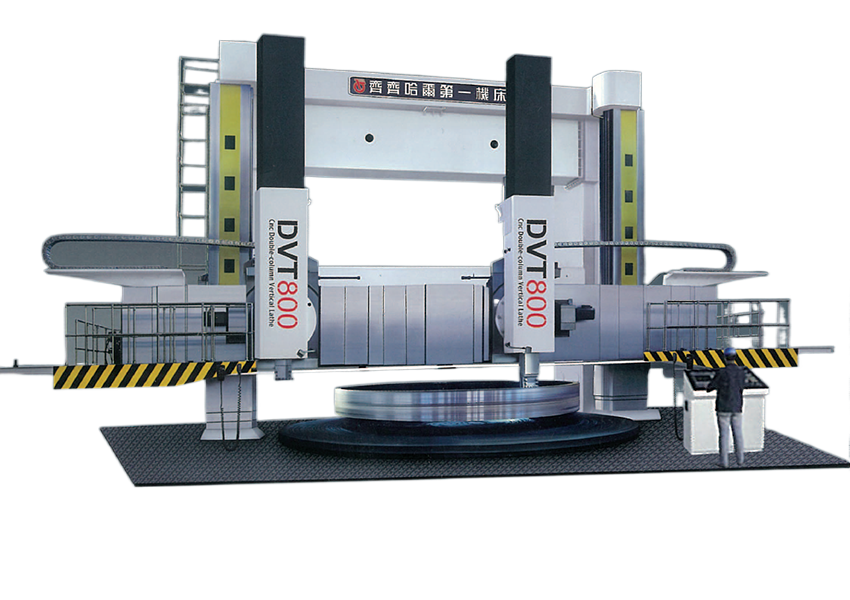

DVT 630-2500 Series - Large Double Column Heavy Duty Vertical Lathe

-

The serial machine is special item solve large span, super large duty vertical swing platform design manufacture technique, super wide, super long workpiece's machining process etc. a set key technique.

-

It is adopted torque plate, unloading rail, anti-bending rail and anti-deformation technique to assure large span's cross rail horizontal accuracy stability.

-

Table is adopted new type connecting technical structure, three sets bearing spindle structure, mature single story, double story hydrostatic guideway and oil film testing technical, which is assure that table large loading, high accuracy stability running.

-

Gantry moving machine is adopted synchronistic servo technical to assure gantry movement, feed correct stability.

-

The serial machine can supply high accuracy, high rotating speed products with milling, boring thread, grinding and kinds tools handle etc. function. Machining efficiency is improved.

| Item | Max.machining diameter | Diameter of table | Max.machining highness(mm) |

Max.weight ofworkpiece (ton) | Horizontal stroke of head (mm) | Cutting force of right head (kn) | Cutting force of left head (kn) |

| DVT630 | 6300 | 5700/6000 | 3150 3500 4000 4500 5000 | 63/80/100/150 | -50-3400 | 80 100 125 | 63 80 100 |

| DVT800 | 8000 | 7100 | 4000 4500 5000 5500 | 125/200/300 | -50-4400 | 100 125 | 80 100 |

| DVT1000 | 10000 | 7100/8000 | 4000 4500 5000 5500 6000 | 125/200/300 | -50-5400 | 101 125 | 80 100 |

| DVT1250 | 12500 | 8000/10000 | 5000 5500 6000 | 250/300/400 | -50-6500 | 125 160 | 100 125 |

| DVT1600 | 16000 | 8000/10000 | 5000 6000 6500 | 250/500/600 | -50-8400 | 126 160 | 100 125 |

| Item | Max. torque of worktable (kn.m) | Section of ram (mm2) | Vertical stroke of ram (mm) | Power of main transmission motor (kw) |

Rotating speed of table (r/min) | Rapid speed moving of head (Mm/min) |

Guideway pairs of table |

| DVT630 | 150 315 500 | 280 320 400 | 2000 2500 | 90/110 | 0.32-32/0.25-25 | 4000 | Hydrostatic |

| DVT800 | 500 640 | 320 400 | 2000 2500 2500 2750 |

90/110 | 0.25-25/0.2-20 | 4000 | Hydrostatic |

| DVT1000 | 640 | 321 400 | 2500 2750 3000 | 132/160 | 0.2-20/0.25-25 | 4000 | Hydrostatic |

| DVT1250 | 640 | 400 460 | 2500 2750 2750 3000 3000 |

132/160 | 0.2-20/0.16-16 | 4000 | Hydrostatic |

| DVT1600 | 800 | 400 460 | 2750/3000/3500 | 132/160 | 0.16 16 | 4000 | Hydrostatic |

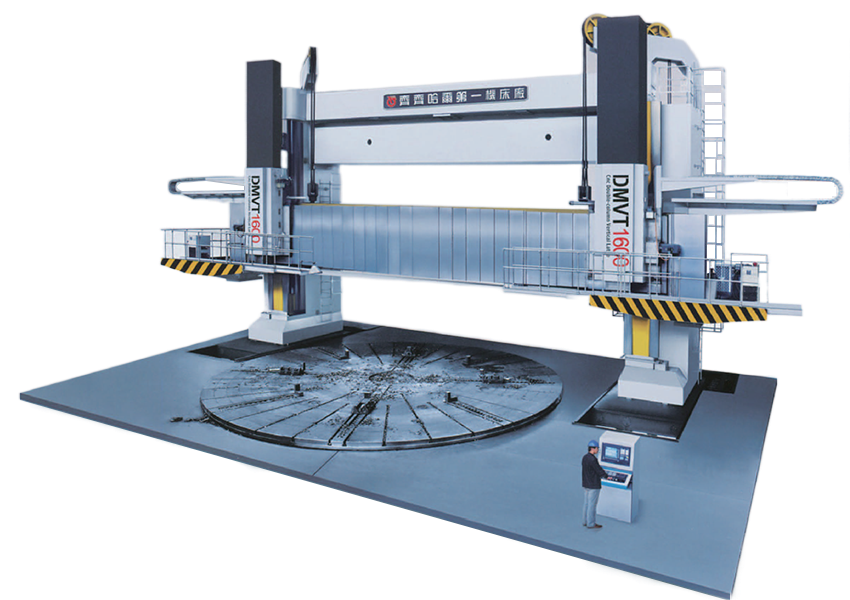

Vertical Turning Milling CNC Lathe Of Heavy Gantry Moving

| Item | Max.machining diameter | Diameter of table | Max.machining highness(mm) |

Max.weight ofworkpiece (ton) | Horizontal stroke of head (mm) | Cutting force of right head (kn) | Cutting force of left head (kn) | Stroke of gantry moving (mm) | Velocity of gantry moving (mm/min) |

| DVT1600 | 16000 | 8000/10000 | 5500/6000 | 250/400 | -50-6570 | 125 160 | 100 125 | 5300 | 100 |

| DVT2500 | 25000 | 10000 | 6000 | 500/600 | -50-8450 | 126 160 | 100 125 | 12350 | 100 |

| Item | Max. torque of worktable (kn.m) | Section of ram (mm2) | Vertical stroke of ram (mm) | Power of main transmission motor (kw) |

Rotating speed of table (r/min) | Rapid speed moving of head (Mm/min) |

Guideway pairs of table |

| DVT1600 | 800 | 400 460 | 3000 | 160 | 0.16 - 16 | 4000 | Hydrostatic |

| DVT2500 | 800 | 400 460 | 3000 | 160 | 0.16 - 16 | 4000 | Hydrostatic |