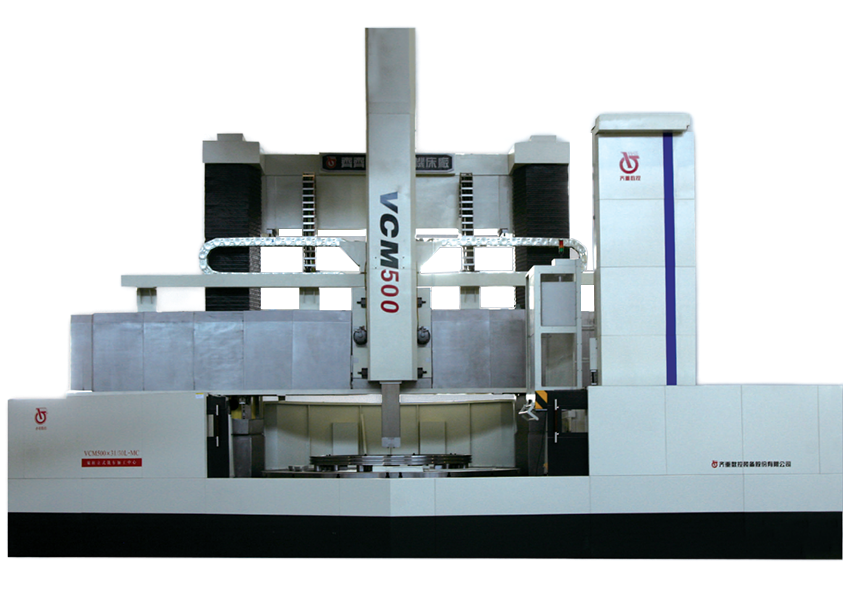

VCM High Speed High Accuracy Series

This machine is suitable for finely machining the large duty workpiece and complex parts in the industries of astronautical, aviation, energy sources, military and ship industry etc. fields. Clamping once it can achieve turning, milling, drilling, boring, grinding, tapping etc. process.

- Table adopts AC servo double driven structure with simple structure and stable & reliable performance.

- Table adopts constant current hydrostatic guideway with features of high loading capacity, high speed and high accuracy. The speed of table can reach world leading level compared with the same type machine.

- Horizontal moving of milling tool post adopts AC servo double driven structure which realizes high speed and high accuracy.

- Vertical moving of ram adopts hydrostatic guideway which realizes high speed, high accuracy and strong cutting force.

- Equipped with milling magazine, turning magazine to change milling head and tool automatically.

- Equipped with workpiece and tool testing automatically device.

| Parameters | Unit | VC315 VCM315 |

VC350 VCM350 |

VC400 VCM400 |

VC500 VCM500 |

VC630 VCM630 |

|

| Table dia. | mm | 2830 | 3150 | 3600 | 4500 | 5700 | |

| Max.machining dia. | mm | 3150 | 3500 | 4000 | 5000 | 6300 | |

| Max.machining height | mm | 2000/2500 | 2000/2500 | 2000/2500/3150 | 2500/3150/4000 | 3500/4000/5000 | |

| Max.loading capacity of table | t | 40 | 40 | 40 | 50 | 63 | |

| Table guideway type | Hydrostatic | Hydrostatic | Hydrostatic | Hydrostatic | Hydrostatic | ||

| Power of table main motor | kW | 2-55 | 2-55 | 2-55 | 2-55 | 2-80 | |

| Turning speed of table | r/min | 200 | 160 | 160 | 125 | 100 | |

| Milling speed of table | r/min | 0.0002-2 | 0.0002-2 | 0.0002-2 | 0.0002-2 | 0.0001-1 | |

| Max.torque of table | kNm | 80 | 80 | 80 | 100 | 125 | |

| Section size of ram | Turning | mm | 240x240 | 240x240 | 240x240 | 240x240 | 320x320 |

| Milling | mm | 320x320 | 320x320 | 320x320 | 320x320 | 320x320 | |

| Type of ram guideway | Hydrostatic | Hydrostatic | Hydrostatic | Hydrostatic | Hydrostatic | ||

| Max.travel of ram Zaxis | mm | 1600 | 1600 | 1600/2000 | 1600/2000 | 2000/2500 | |

| Rapid travel of head(X/Z axis) | mm/min | 20000/10000 | 20000/10000 | 20000/10000 | 20000/10000 | 20000/10000 | |

| Max.cutting forcewhen turning | Turning | KN | 35 | 35 | 35 | 35 | 50 |

| Milling | KN | 50 | 50 | 50 | 50 | 50 | |

| Spindle speed of boring milling | r/min | 10-2500 | 10-2500 | 10-2500 | 10-2500 | 10-2500 | |

| Spindle torque of boring milling | N.m | M1=1000 M2=1400 | M1=1000 M2=1400 | M1=1000 M2=1400 | M1=1000M1=1000 M2=1400 | M1=1000M1=1000 M2=1400 | |

| Spindle power of boring milling | kW | S1=28 S2=38 | S1=28 S2=38 | S1=28 S2=38 | S1=28 S2=38 | S1=28 S2=38 | |

Spindle hole taper |

Turning | BT 60/Single tool holder | BT 60/Single tool holder | BT 60/Single tool holder | BT 60/Single tool holder | ISO 50/Single tool holder | |

| Milling | ISO 50 | ISO 50 | ISO 50 | ISO 50 | ISO 50 | ||

| Elevating speed of crossrail | mm/min | 360 | 360 | 360 | 360 | 410 | |

| Crossrail classification location pitch | mm | 250 | 250 | 250 | 250 | 250 | |

| Table face radial runout | mm | 0.006 | 0.007 | 0.008 | 0.01 | 0.012 | |

| Face runout of table face | mm | 0.006 | 0.007 | 0.008 | 0.01 | 0.012 | |