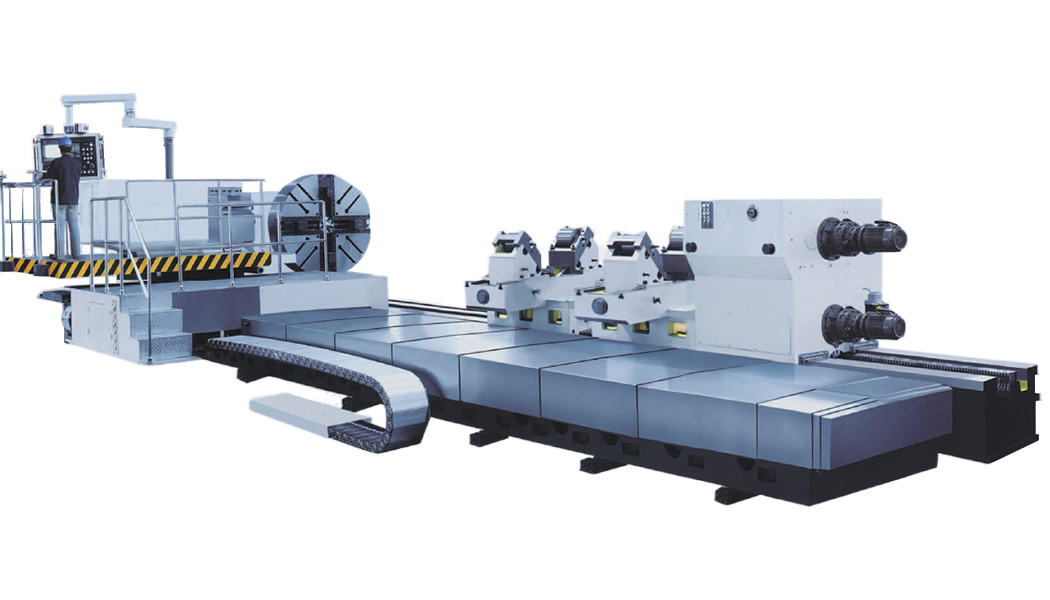

HT III Series

- Double deck wall and reduce noisy shockproof' s headstock body, which is adopted high accuracy rolling spindle bearing, through shaft mode high swivel accuracy short spindle structure with high accuracy, low noisy.

- Base of head stock’s case mode structure, inside ring shape enforce rib prevent heat floating movement's heat symmetry structure.

- The left right tool plate of carriage is suitable for strength cutting. Cutting rigid is well with CAPOT tools interface.

- Unique hydrostatic worm bar, worm rack technique, single cavity, single pump constant flowing close mode hydrostatic guideway pairs with large loading, high accuracy and high stability.

- Position feedback line measurement system optical ruler is fixed on the X/Z axis of carriage.

- Bed is adopted high strength low stress advance cast iron pouring, rectangle guideway with well heat stability, large supporting, cutting stability.

- Whole set mode case body's tailstock, mandrel of high accuracy rolling bearing supporting, short taper handle flange mode center with heat deformation compensation structure. Projection force's display function. Rotating accuracy is advance with high rigid and high reliability.

- Boring, grinding, polish etc. function accessories are selected, complex function is very strength.

| Parameters | Units | HT III 160 | HT III 200 | HT III 250 | HT III 315 | HT III 350 | HT III 420 | HT II 500 | HT III 630 |

| Max. swivel diameter on the bed | mm | 1600 | 2000 | Ø2500 | Ø3150 | 3500 | 4200 | Ø5000 | 6300 |

| Max. turning diameter over carriage | mm | Ø1250 | 1600 | 2000 | 2500 | 2800 | 3500 | 4000 | Ø5000 |

| Max. length of workpiece | mm | 2000-18000 | 2000-18000 | 2000-25000 | 2000-25000 | 2000-25000 | 2000-25000 | 2000-25000 | 2000-25000 |

| Max. weight between center | t | 40 | 40/50/63 | 32/40/50/63/ 80/125/180 |

32/40/50/63/ 80/125/180/300 |

80/125/180 /300/400 |

80/125/180 /300/400 |

80/125/180 /300/400 |

160/250/350 |

| Pange of spindle speeds | r/min | 0.8-160 | 0.8-160 | 0.8-160/0.63- 125/0.5-100 |

0.63-125 0.5-100 |

0.63-125/0.5- 100/0.4-80 |

0.63-125/0.5- 100/0.32-63 |

0.63-125/0.5- 100/032-63 |

0.32-63 |

| Dia of faceplate | mm | 1250 | 1600 | 02000/0 2500 | 02000/0 2500 | 0200/0 2500 /03200 |

02500/0 3200 | 0 2500/0 3200 | 3200 |

| Max torque of faceplate | KN.m | 60 | 60-72 | 80-200 | 80-250 | 125-280 | 125-350 | 150-350 | 220-400 |

| Max cutting force of carriage | KN | 80 | 80-90 | 90-200 | 90-200 | 125-200 | 125-200 | 150-200 | 125-200 |

| Power of main motor | kW | 75 | 90 | 110-160 | 110-200 | 132-200 | 132-225 | 160-225 | 160-225 |