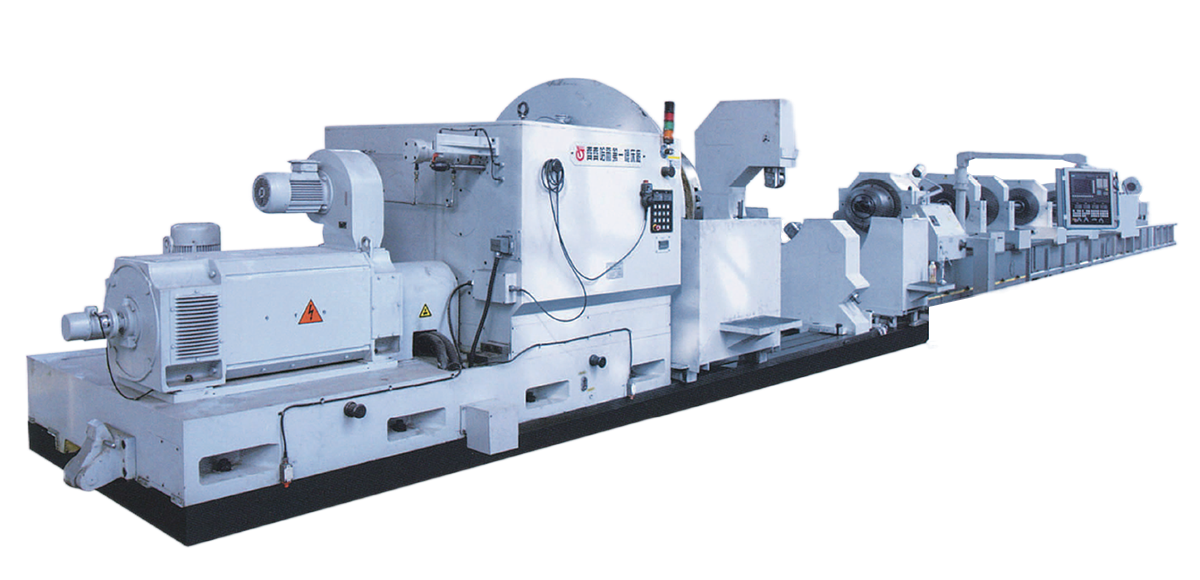

DDB II Series - Deep Drill Boring Lathe

- Total layout of DDBII type deep hole drilling boring lathe is headstock movable mode.

- It is main used for machining workpiece of cast iron, cast steel, forged steel etc. material, which is performed drilling hole, counter-boring, fine boring, etc. deep hole machining.

- High low layout for bed of workpiece and bed of drilling

- The headstock is mounted on the sliding plate of headstock, and can move or be clamped on workpiece bed according to workpiece length.

- Rotating (drilling) or fixed (for boring) tools can be equipped for drilling rod box.

- The drilling rod box is installed on the drilling rod feed sliding plate. The drilling rod movement have three transmission modes, can selected by according to conditions. The first is driven by reducer and screw lead via D.C motor. The second is transmission of gear-rack. The third is transmission of double gears-rack.

- The machine is equipped with 828D CNC system and feedback device for Z axis.

- The turning face's tool post is equipped with turning workpiece face's machine.

- The machine can be equipped with horning function with feed device and cooling system.

| Parameters | Unit | DDB || 63 xL/W(P-NC) |

DDB II 80 xL/W(P-NC) |

DDB || 100 xL/W(P-NC) |

DDB || 160 xL/W(P-NC) |

| Diameter of Max.boring hole | mm | 630 | 800 | 1000 | 1600 |

| Diameter of Max.drilling hole | mm | 150 | 150 | 150 | 150 |

| Depth of Max.drilling boring hole | mm | 5000-20000 | 5000-20000 | 5000-20000 | 5000-20000 |

| Length of Max.workpiece | mm | 5000-20000 | 5000-20000 | 5000-20000 | 5000-20000 |

| Diameter of Max.workpiece swivel | mm | 2200 | 2500 | 2800 | 3200 |

| Weight of Max.workpiece | t | 40/50 | 63/80/100 | 125/150 | 200/300 |

| Max.torque of headstock'spindle | N.m | 80000 | 100000 | 120000 | 150000 |

| Range of headstock spindle rotating speed | r/min | 0.8-160 | 0.63-125 | 0.5-100 | 0.4-80 |

| Steps of headstock'spindle speed changed | Stepless(Mechanical II step) | Stepless(Mechanical II step) | Stepless(Mechanical II step) | Stepless(Mechanical II step) | |

| Max.torque of drillinng bar box'spindle | N.m | 8500 | 8500 | 8500 | 8500 |

| Range of drilling rod box'spindle rotating speed | r/min | 5-500 | 5-500 | 5-500 | 5-500 |

| Steps of drilling rod box'spindle speed change | Stepless(Mechanical II step) | Stepless(Mechanical II step) | Stepless(Mechanical II step) | Stepless(Mechanical II step) | |

| Range of drilling rod box feed rate | mm/min | 1.5-300 | 1.5-300 | 1.5-300 | 1.5-300 |

| Velocity of drilling rod box rapid speed | mm/min | 3000 | 3000 | 3000 | 3000 |

| Steps of drilling rod feed box speed changed | Stepless | Stepless | Stepless | Stepless | |

| Max.flow of cooling system | L/min | 800 | 800 | 800 | 800 |

| Max.pressure of cooling system | MPa | 2.5 | 2.5 | 2.5 | 2.5 |

| Diameter of chuck | mm | 1600 | 2000 | 2500 | 3000 |

| Diameter of chuck holding | mm | 350-1250 | 400-1500 | 500-2000 | 500-2000 |

| Diameter of close mode steady supporting | mm | 350-800 | 400-900 | 500-1000 | 600-1100 |

| Diameter of open mode steady supporting | mm | 350-1250 | 800-1600 | 800-2000 | 800-2200 |

| Power of headstock main motor | KW | 90 | 110 | 125 | 160 |

| Power of drilling rod box's main motor | KW | 55 | 55 | 55 | 55 |

| Feed motor - Transmission of screw lead nut | KW | 17 | 17 | 17 | 17 |

| Feed motor - Transmission of gear rack | N.m | 65 | 65 | 65 | 65 |

| Power of cooling pump's motor | KW | 22 | 22 | 22 | 22 |