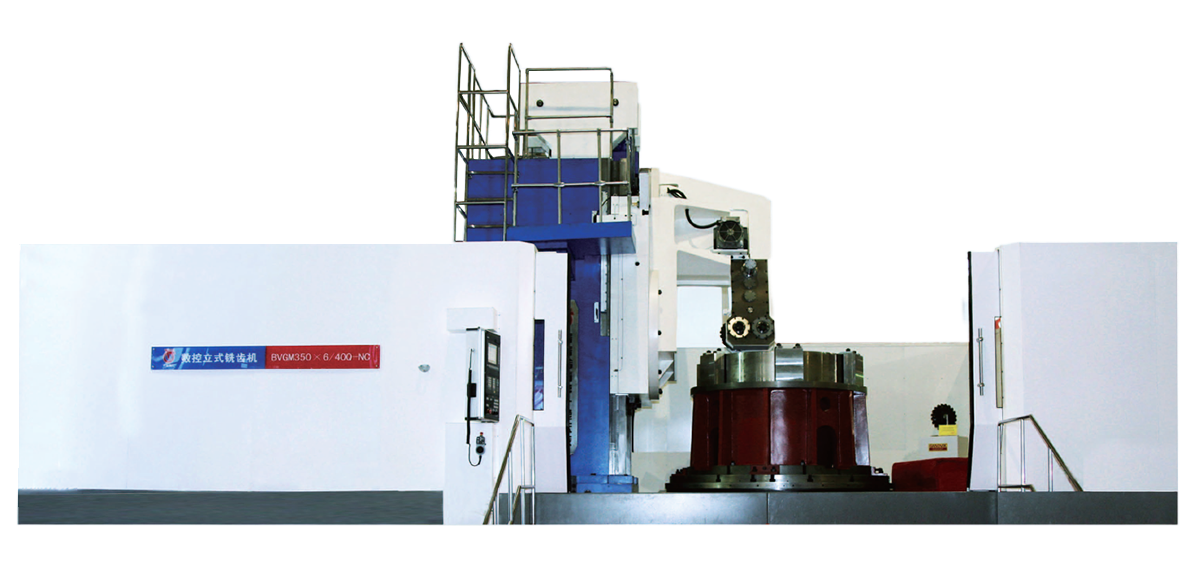

BVGM

- The series product is a high reliability, high accuracy, good efficiency metal cutting machine. It is realized rough, finely machining for inner tooth straight gear or taper gear by C axis, Z axis simultaneously feed together with highspeed rotating with round tool disc.

- It is performed machining roughly and finely for inner and outer straight gear or inner race profile of taper gear on the swivel supporting parts.

- The series is adopted advance metal cutting method. It is realized rough, finely machining for inner tooth of straight gear or taper gear by C axis, Z axis simultaneously feed and forceful milling with round tools disc.

- It is international advanced metal cutting tools for single tooth machining, so production efficiency can be improved 10 times than common gear hobbing machine.

- CNC system is SIEMENS 828D.

| Parameters | Unit | BVGM250X6/40P-NC | BVGM315X6/40P-NC | BVGM350 X6/40P-NC |

BVGM400X6/40P-NC | BVGM500 X6/40P-NC |

BVGM630X6/40P-NC | BVGM800X6/50P-NC |

| Max. machining dia. | mm | 2500 | 3150 | 3500 | 4000 | 5000 | 6300 | 8000 |

| No.of machining tooth | Random | Random | Random | Random | Random | Random | Random | |

| Max. machining module of outer milling | mm | 25 | 25 | 25 | 25 | 36 | 36 | 40 |

| Max. machining module of inner milling | mm | 25 | 25 | 25 | 25 | 25 | 25 | 25 |

| Helix angle of max. outer race | deg | ±25 | ±25 | ±25 | ±25 | ±25 | ±25 | |

| Helix angle of max. inner race | deg | ±25 | ±25 | ±25 | ±25 | ±25 | ±25 | ±25 |

| Max. machining height | mm | 600 | 600 | 600 | 600 | 600 | 600 | 600 |

| Max. machining thickness | mm | 400 | 400 | 400 | 400 | 400 | 400 | 400 |

| Power of milling tool post motor | kW | 55 | 55 | 55 | 55 | 55 | 55 | 55 |

| Speed range of milling tool | r/min | 25-150 | 25-150 | 25-150 | 25-150 | 25-150 | 25-150 | 25-150 |

| Max. dia of milling tool disc | mm | φ500 | φ500 | φ500 | φ500 | φ500 | φ500 | φ500 |

| Width of milling tool disc | mm | 120 | 120 | 120 | 120 | 120 | 120 | 120 |

| Table dia. | mm | 2000 | 2500 | 2500 | 3150 | 4000 | 4500 | 5000 |

| Max. speede range of table | r/min | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | 0.2 |

| Max. weight of workpiece | t | 40 | 40 | 40 | 40 | 40 | 40 | 50 |

| Feed speed of X aixs | mm/min | 0.1-1000 | 0.1-1000 | 0.1-1000 | 0.1-1000 | 0.1-1000 | 0.1-1000 | 0.1-1000 |

| Feed speed of Z aixs | mm/min | 0.1-1000 | 0.1-1000 | 0.1-1000 | 0.1-1000 | 0.1-1000 | 0.1-1000 | 0.1-1000 |

| Table index accuracy | ±3” | ±3" | ±3" | ±3” | ±4” | ±4" | ±4" | |

| CNC system | 828D | 828D | 828D | 828D | 828D | 828D | 828D |